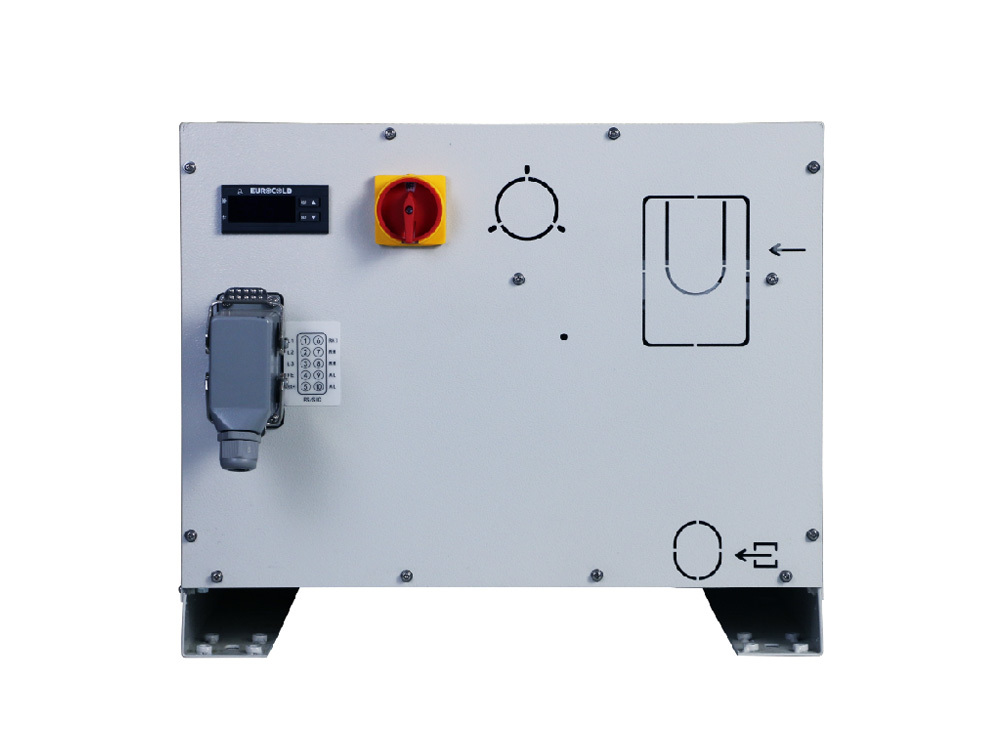

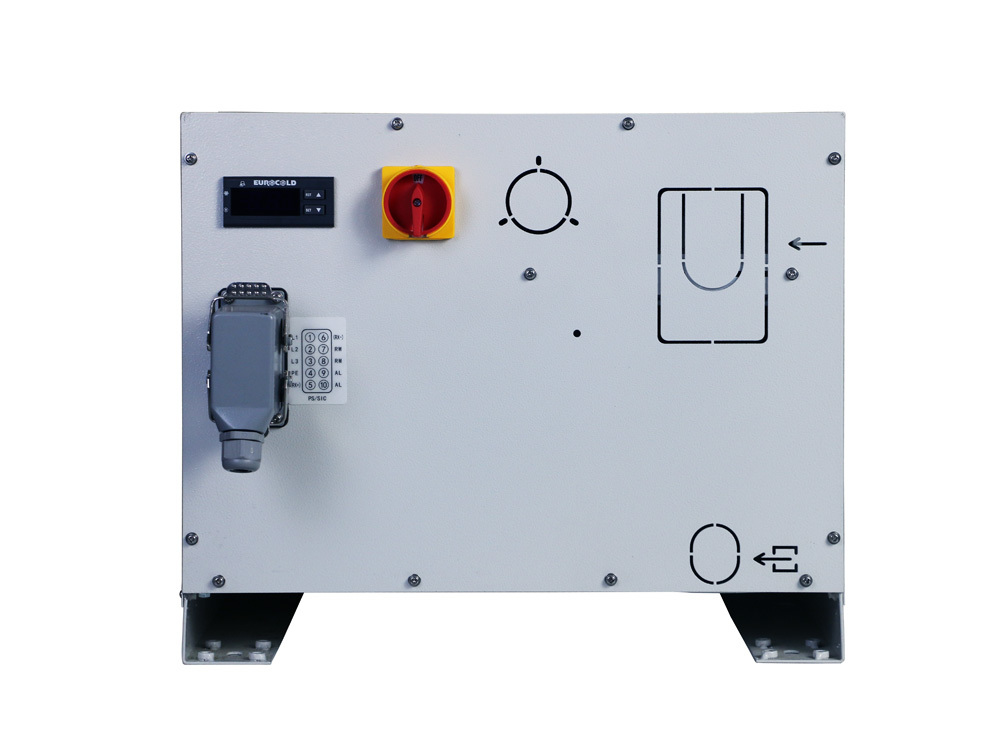

ACO-035

Automatic control temperature controller, simple and intuitive operation. The device has two control modes of "fixed temperature" and "room temperature coherence", which can be switched freely according to actual needs.

Keywords:

Category:

Telephone:

E-mail:

Product Details

Parameters

|

Items |

ACO-035 |

|

|

cooling capacity(KW) |

3.5 |

|

|

Power(KW) |

2.1 |

|

|

Power source |

□1/220 □3/380 □3/220 □50HZ □60Hz |

|

|

Precision (℃) |

±1.5(±0.1 Option PID) |

|

|

Range of setting(℃) |

Fixed:15-40:Variable:±9 |

|

|

Ambinet temperature(℃) |

5-40 |

|

|

Oil viscosity (cSt) |

2-68 |

|

|

P:Pump |

Flow rate(L/min) |

20 |

|

Pressure (bar) |

10 |

|

|

T:Tank |

Volum(L) |

25 |

|

Optional item(customized) |

F: Flow switch |

□ |

|

L: Level switch |

□ |

|

|

H: Heater |

□ |

|

|

W: Wheel |

□ |

|

|

Inlet/Outlet Size |

G3/4" |

|

|

Noise (dB) |

65 |

|

|

Weight(KG) |

70 |

|

|

Refrigerant |

R-134a |

|

|

Shape |

Dimension (mm) |

453*465*923 |

|

Drawing code |

B0/B1 |

|

Application Range

1.CNC machine tool mechanical spindle, low speed motorized spindle

2.CNC machine tools, hydraulic press and all kinds of mechanical equipment, hydraulic station, lubrication station

3.Cooling the processing fluid of the discharge machining equipment

4.Reducer lubrication, cooling system, such as: Germany ZF reducer, Italy BF reducer and homemade gearbox, etc

Functions and features

1.Automatic control temperature controller, simple and intuitive operation. The device has two control modes of "fixed temperature" and "room temperature coherence", which can be switched freely according to actual needs.

2.With a variety of protection functions and provide passive alarm terminals, the fault signal feedback to the CNC system of the machine;

3.Provide remote start port, easy to realize the linkage control of the host equipment and the oil cooler ;

4.Optional RS485 communication interface, can realize the communication with the host;

5.To prevent the spindle of CNC machine tool from affecting the machining accuracy due to oil temperature changes;

6.To prevent CNC machine tool spindle center deviation or thermal deformation, stabilize the accuracy of the machine tool and extend the service life of the machine tool;

7.Prevent oil deterioration caused by high oil temperature, maintain oil viscosity characteristics, stabilize oil pressure, avoid oil shock.

Product Consulting

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!